1. Karɓi aikin

Littafin ɗawainiya don gyare-gyaren sassa na filastik galibi ana gabatar da shi ta mai tsara ɓangaren, kuma abun cikin sa shine kamar haka:

1) Zane-zanen da aka yarda da su na sassa na yau da kullun, kuma suna nuna matsayi da bayyana gaskiyar filastik.

2) Umarni ko buƙatun fasaha don sassan filastik.

3) Abubuwan samarwa.

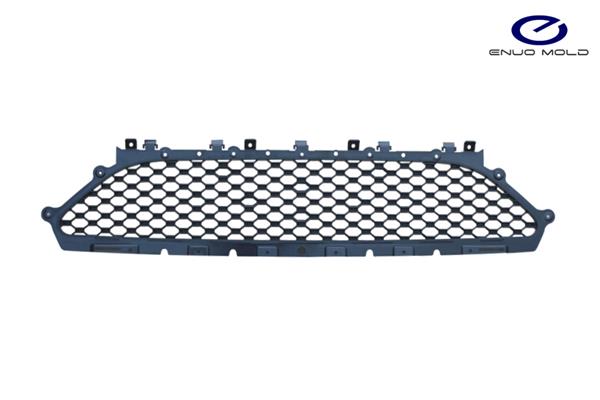

4) Samfuran sassan filastik.

Yawanci littafin aikin ƙirar ƙira yana ba da shawara ta mai yin aikin filastik bisa ga littafin ɗawainiya na ɓangaren filastik da aka ƙera, kuma mai ƙirar ƙirar ƙirar ƙirar ƙirar ƙirar ta dogara da littafin aiki na ɓangaren filastik da aka ƙera da littafin aikin ƙirar ƙira.

2. Tattara, bincika, da narkar da bayanan asali

Tattara da tsara ƙirar sassa masu dacewa,yin gyare-gyaretsari, gyare-gyaren kayan aiki, kayan aikin injiniya da kayan aiki na musamman don amfani lokacin zayyana ƙira.

1) Nuna zane-zane na sassan filastik, fahimtar manufar sassan, bincika buƙatun fasaha na sassan filastik, kamar haɓakawa da daidaiton girman.Misali, menene buƙatun sassa na filastik dangane da bayyanar, bayyanar launi, da aiki, ko tsarin geometric, gangara, da abubuwan da ake sakawa na sassan filastik suna da ma'ana, ƙimar da aka yarda da lahani na gyare-gyare kamar alamomin walda da ramukan raguwa. , da kuma ko an rufe su ko a'a.Bayan aiwatarwa kamar taro, electroplating, bonding, da hakowa.Zaɓi girman tare da mafi girman daidaitaccen ɓangaren ɓangaren filastik don bincike, kuma duba idan ƙimar juriyar gyare-gyaren da aka ƙididdige ta yi ƙasa da na ɓangaren filastik, kuma ko ɓangaren filastik wanda ya dace da buƙatun ana iya ƙera shi.Bugu da ƙari, wajibi ne a fahimci ma'auni na tsarin filastik da gyaran gyare-gyare na filastik.

2) Narke bayanan tsari, bincika ko hanyar yin gyare-gyare, ƙirar kayan aiki, ƙayyadaddun kayan aiki, nau'in tsarin ƙirar da sauran buƙatun da aka gabatar a cikin littafin aikin aiwatarwa sun dace kuma ko ana iya aiwatar da su.

Ya kamata kayan gyare-gyaren ya dace da ƙarfin buƙatun sassa na filastik, kuma suna da ruwa mai kyau, daidaituwa, isotropy, da kwanciyar hankali na thermal.Dangane da manufar sassa na filastik, kayan gyare-gyaren ya kamata ya dace da buƙatun rini, plating na ƙarfe, kayan ado na kayan ado, elasticity mai mahimmanci da filastik, nuna gaskiya ko akasin halayen tunani, adhesiveness ko weldability.

3) Ƙayyade hanyar yin gyare-gyare

Yi amfani da hanyar matsa lamba kai tsaye, hanyar matsi ko hanyar allura.

4) Zaɓi kayan gyare-gyare

Ana yin gyare-gyare bisa ga nau'in kayan aikin gyaran gyare-gyare, don haka ya zama dole don sanin aikin, ƙayyadaddun bayanai, da halaye na kayan aiki daban-daban.Alal misali, ga wani allura inji, da wadannan ya kamata a fahimci cikin sharuddan bayani dalla-dalla: allura iya aiki, clamping matsa lamba, allura matsa lamba, mold shigarwa size, ejection na'urar da size, bututun ƙarfe rami diamita da bututun ƙarfe mai siffar zobe radius, sprue hannun riga sakawa zobe size. Matsakaicin mafi ƙanƙara da ƙaƙƙarfan ƙura, bugun samfuri, da sauransu, da fatan za a koma zuwa sigogi masu dacewa don cikakkun bayanai.

Wajibi ne a fara ƙididdige ma'auni na ƙirar kuma ƙayyade ko za'a iya shigar da ƙirar kuma a yi amfani da shi akan na'urar allurar da aka zaɓa.

5) Tsari na musamman

(1) Ƙayyade nau'in mold

Kamar latsa gyare-gyare (buɗe, rufewa, rufewa), gyare-gyaren simintin gyare-gyare, ƙirar allura, da sauransu.

(2) Ƙayyade babban tsari na nau'in mold

Zabar da manufa mold tsarin ne don sanin zama dole gyare-gyaren kayan aiki da manufa adadin cavities, sabõda haka, mold kanta iya saduwa da bukatun da tsari fasaha da kuma samar da tattalin arziki na filastik part karkashin cikakken abin dogara yanayi.Abubuwan da ake buƙata na fasaha don sassan filastik shine tabbatar da siffar geometric, ƙarewar saman da daidaiton girman sassan filastik.Abubuwan da ake buƙata na tattalin arziƙi na samarwa shine don sanya farashin sassa na filastik ƙasa, ingantaccen samarwa, ƙirar ƙira na iya aiki gabaɗaya, tsawon rayuwar sabis, da ceton aiki.

Lokacin aikawa: Satumba-22-2021